Transforming problematic, no-value, waste streams into high value, concentrated H2 and CO2

Waste generation is a common challenge faced by numerous industries, manifesting as waste gases, liquids, or solid residues from processes, reactions, equipment cleaning and combustion.

The safe disposal of such waste is important to prevent environmental contamination and health hazards.

To address this challenge many companies which generate gaseous/liquid waste pay to have it collected and centrally incinerated due to the variability in composition and toxicity. The disposal of such waste without harnessing its potential represents a missed opportunity for resource recovery and sustainable energy generation, as well as being costly for the company that generates it.

In addition, there is a pressing need for industrial processes to transition to hydrogen fuels as a cleaner and more sustainable energy source to power their operations. By embracing hydrogen, industries can significantly reduce their greenhouse gas emissions, mitigate air pollution, and foster a greener and more resilient future for both the environment and their bottom line.

H2Upgrade is a technology developed by Prof. Stuart Scott, Dr Ewa Marek, and Abu Fasim from the University of Cambridge in collaboration with Dr Rob Grant from GR2L and which allows for the conversion of costly and environmentally damaging waste streams into clean hydrogen fuel, allowing industrial partners to clean up their processes and valorise their waste.

The inventors are now looking to commercialise the technology via a new spinout company, H2Upgrade and are keen to speak with potential partners, investors and customers.

Technology overview

H2Upgrade is a two-stage operation. Initially, hydrocarbon wastes are catalytically converted into food-grade CO2 and water. The catalyst is then regenerated, simultaneously producing high-purity H2 from the recycled water.

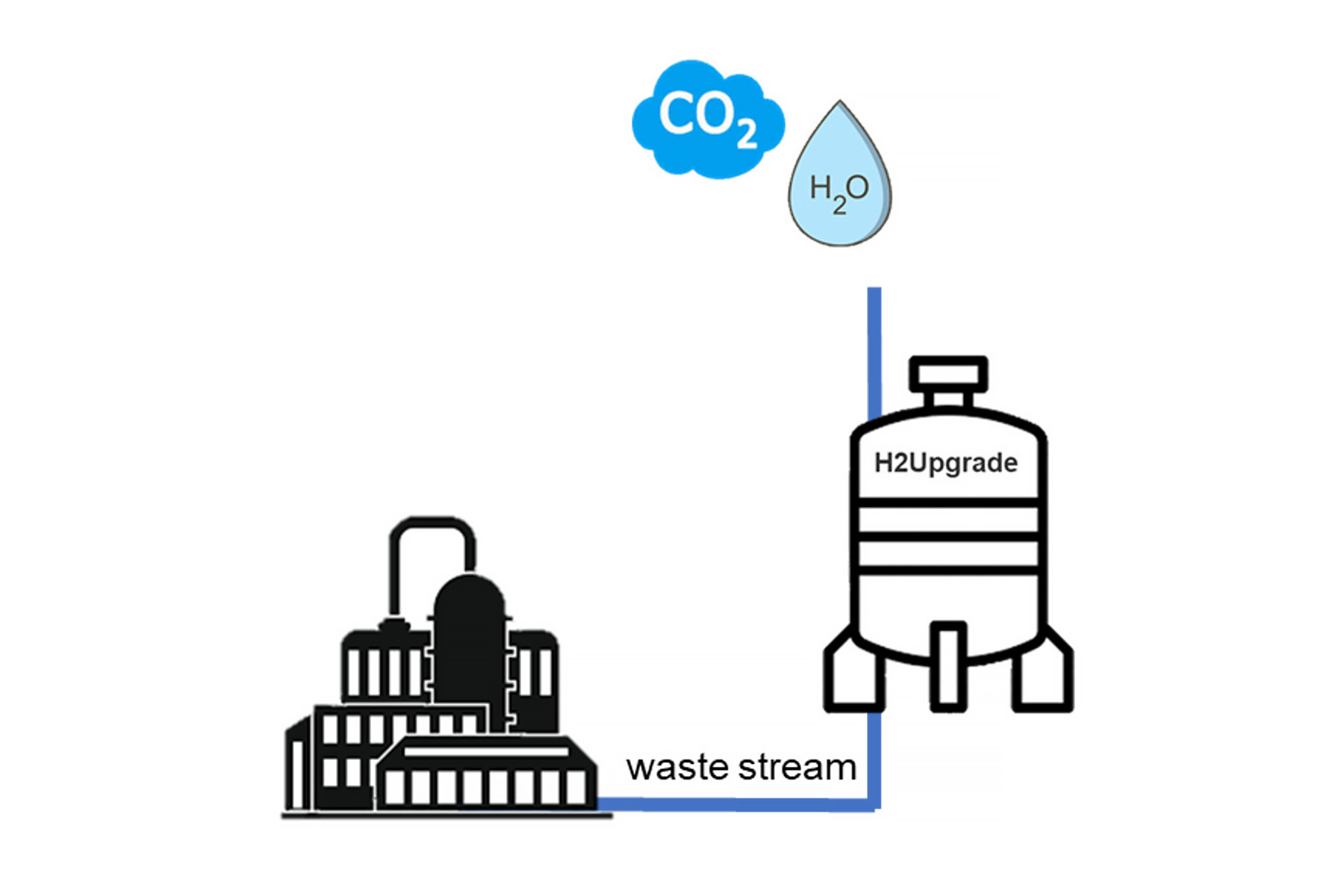

Step 1: Pre-activation of the H2Upgrade material using industrial waste streams (dilute gases, solvents). After liquifying H2O the remaining CO2 is pure – ready for storage or selling (e.g. for food production).

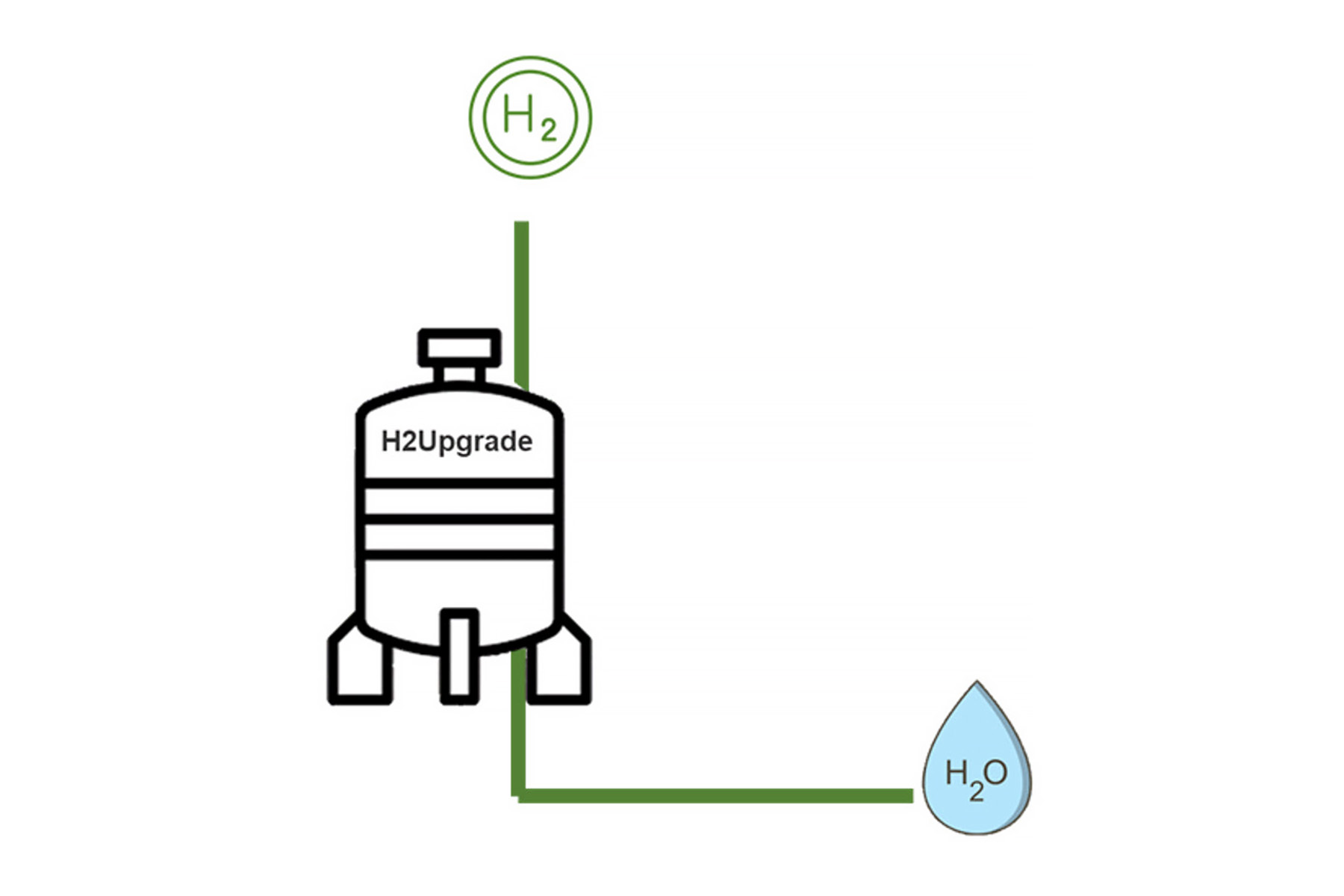

Step 2: Pre-activated materials pull out oxygen from H2O producing H2. High concentrations of H2 (up to 100%) can be stored or used in-house. H2Upgrade materials are made of abundant and inexpensive metals (Fe, Cu).

Benefits

- Transforms low-value waste streams into high-value concentrated H2 (depending on the waste source, potentially ultra-green hydrogen) to be sold or used as hydrogen fuel at the site

- Reduction of GHG emissions – produced CO2 is ready to capture/utilise

- Mobility and flexibility of H2Upgrade units – mobile units to offer waste management service, compatible with various wastes

- Simplicity – delivering an efficient on/off technology realised in medium-scale units

- Reliability, maturity, scalability – the 2-step technology can be designed and scaled as modular installations

Applications

- Waste management companies (to upgrade collected waste streams, producing H2 and pure-CO2, selling both products for profit)

- SME-producing waste streams (for example: food and beverage processing, ink/paint production, and chemical companies)

- H2 industrial users

Inventors

Dr Ewa Marek | Department of Chemical Engineering and Biotechnology

Dr Ewa Marek is a lecturer in the Department of Chemical Engineering and Biochemistry whose research group focuses on negative and net-zero energy technology and sustainable processes and processing.

Professor Stuart Scott | Department of Engineering

Prof Stuart Scott is a professor of energy and thermodynamics at the University of Cambridge whose research is focused on carbon capture and other processes for the abatement of CO2.

A Cambridge alumni, Dr Rob Grant has been a director of Gas Recycling and Recover Ltd (GR2l) since 2008.

Abu is a PhD student in the Energy Reactions and Carriers research group.