Oterra and Seprify launch sustainable white colouring

VenturesBy integrating Seprify’s patented cellulose-based technology, Oterra will be able to offer customers a clean-label and renewable alternative that matches the opacity, brightness and whitening effect of titanium dioxide while significantly reducing environmental impact.

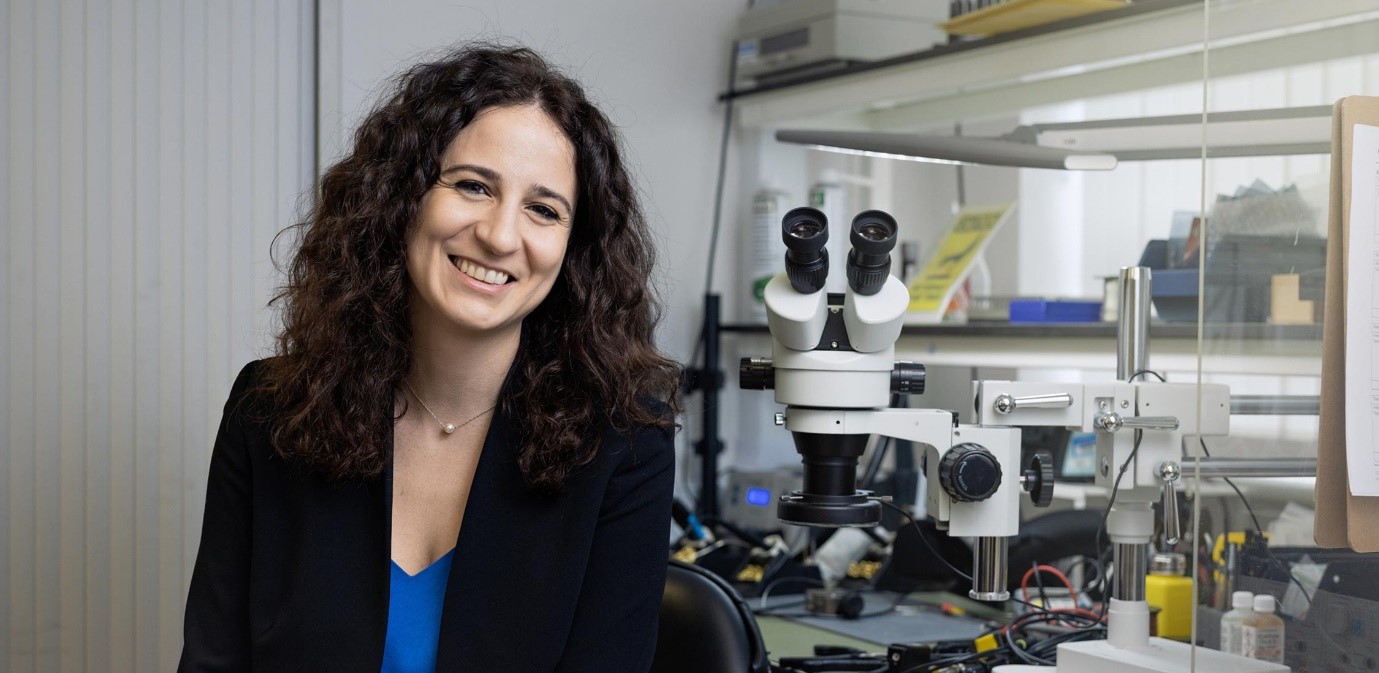

Seprify, a Swiss spinout from the Yusuf Hamied Department of Chemistry, University of Cambridge, and the University of Fribourg, transforms cellulose, the world’s most abundant biopolymer, into high-performance, plant-based functional ingredients. Its nature-inspired technology delivers safe, biodegradable alternatives to conventional whiteners and texturisers, enabling brands to reduce reliance on titanium dioxide and fossil-based polymers while maintaining performance. Seprify’s sustainable material platform supports a wide range of industries, replacing heavy metal ingredients in consumer goods. By combining bio-based materials science with scalable, energy-efficient processing, Seprify helps manufacturers create cleaner, more sustainable products without trade-offs.

The partnership combines Oterra’s global market reach and application expertise with Seprify’s deep materials science and process innovation. The two companies have collaborated for more than two years, testing across more than 15 food categories: from bakery icings, confectionery coatings and sauces to plant-based dairy and meat, and powdered beverages.

Seprify’s proprietary extraction technology produces particles inspired by natural structures that scatter light in a particular way to create a bright white surface.

The titanium dioxide alternative offers easy and rapid dispersion, excellent whitening properties, stability under light, heat and varying pH levels, requires lower dosages compared to other options, and has a neutral flavour and odour.

The new white is produced from microcrystalline cellulose sourced from FSC-certified virgin wood pulp. The wood pulp used is 100% renewable. It is estimated that it creates 80% lower CO2 emissions[1] versus titanium dioxide. It is also nano-compliant and food safe.

“Oterra’s scale and formulation expertise make them the ideal partner to bring our cellulose innovation into mainstream food applications,”

Dr Schertel continued, “Together, we’re proving that natural materials can deliver the same whitening performance as titanium dioxide while cutting CO₂ and meeting new legislative demands. It’s a major step toward making sustainable ingredients the default choice for global food brands.”

“This partnership marks the next chapter in Seprify’s growth: translating scientific validation into commercial momentum,” “By combining Oterra’s global reach with our scalable cellulose platform, we’re accelerating market adoption and building the commercial infrastructure for Seprify’s next growth phase. It’s a clear signal that sustainable ingredients can compete, and win, at industrial scale.”

Oliver Polcher, Chief Business Officer and co-founder of Seprify

“Oterra has developed one of the largest portfolios of natural colours in response to growing consumer demand for alternatives to artificial colours. While we have good, natural raw materials to replace titanium dioxide in selected applications, this new source of white gives us better options for a broader range of food and beverage applications,”

“The sustainability profile of the technology means that Oterra can also get closer to its goals of reducing the amount of carbon dioxide released. Together with Seprify, we’re ensuring that performance, safety, and sustainability go hand in hand for the next generation of food formulations.”

Luc Ganivet, Chief Innovation Officer, Oterra

“Seprify's partnership with Oterra marks a major step in bringing sustainable, plant-based innovation to the global stage. Seprify’s progress shows how visionary, responsible, nature-inspired solutions can deliver real impact for industry and the environment alike.”

Chris Gibbs continued, “We are delighted to see them achieve this important milestone and to support them on their journey.”

The new white is available for customer trials now, with studies already underway across key regions. Beyond food, the partnership also signals wider opportunities for sustainable colour and opacity systems in adjacent markets, reinforcing both companies’ commitment to responsible innovation and materials circularity.

As a registered form of microcrystalline cellulose (MCC), it can be used across food and beverage categories in compliance with EU and US regulations.