Paragon, a trailblazer in sustainable materials innovation, today announced an exclusive option with Cambridge Enterprise, the innovation arm of the University of Cambridge, to innovative green ammonia technology from the lab of Professor Laura Torrente, developed by Dr Collin Smith.

This powerful relationship marks a monumental step toward making accessible, certified green ammonia a global reality, leveraging the best of UK innovation to address climate challenges.

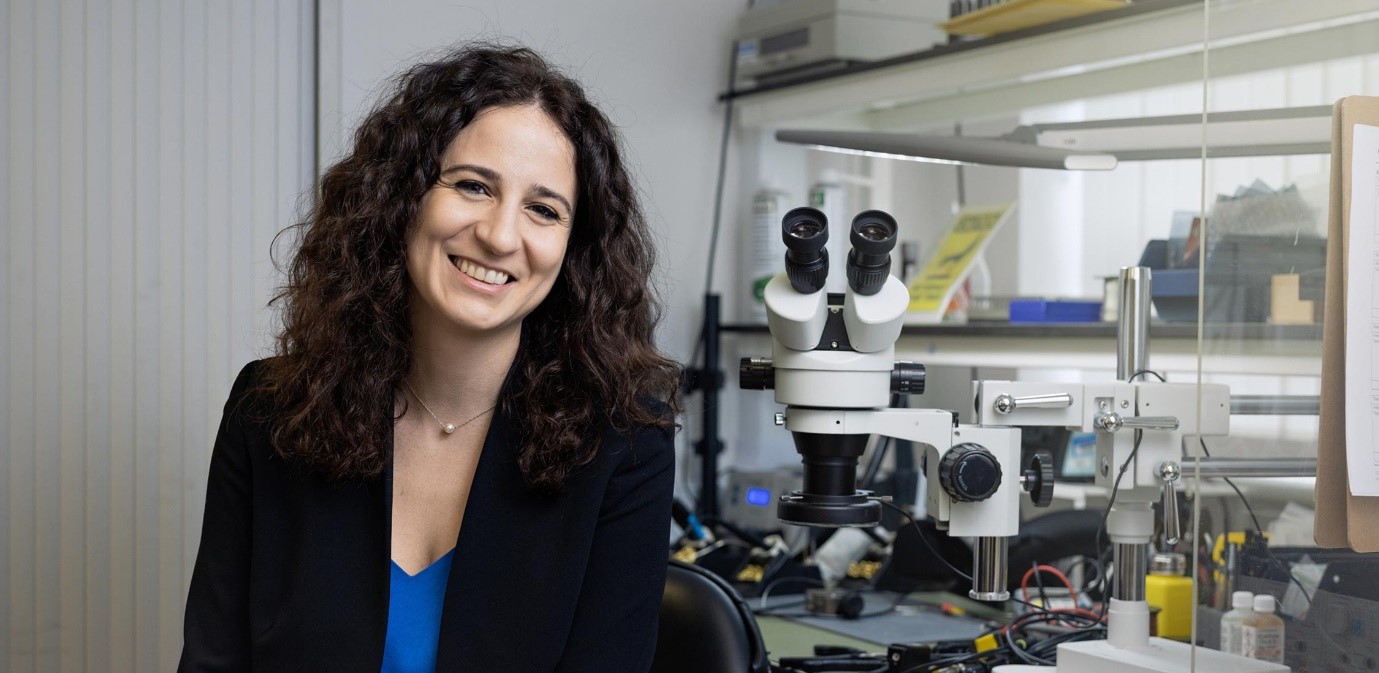

The collaboration merges Paragon’s proprietary Green Hydrogen processing technology—which sources hydrogen feedstock from end-of-waste aluminium—with the University of Cambridge’s world-renowned technical expertise and innovation in sustainable chemical engineering, spearheaded by Professor Laura Torrente in the Department of Chemical Engineering and Biotechnology.

The green ammonia market opportunity

Green ammonia is a critical carbon-free alternative to conventional (grey) ammonia, enabling deep decarbonisation across the agriculture, energy, and transport sectors. Conventional ammonia production currently generates approximately two tonnes of greenhouse gas (GHG) for every tonne of ammonia produced, emissions that will be eliminated by this new process by using green hydrogen. Its use aligns directly with major global decarbonisation mandates, supported by the EU’s CBAM, ETS, and RED III policies. The market for ammonia is projected to grow exponentially to over $60 billion by 2030.

Dual Impact: Agriculture and Hydrogen Transport

- Decarbonising Food Production: Over 70% of global ammonia is used in fertilisers, which are critical for food security. Green ammonia enables fossil-free fertiliser, dramatically reducing emissions from synthetic nitrogen production. This joint solution is poised to democratise access to sustainable fertiliser and accelerate the decarbonisation of global agriculture.

- Efficient Hydrogen Carrier: Green ammonia is also a stable, high-density hydrogen carrier, making it ideal for long-distance energy transport. Transporting hydrogen as green ammonia is a safer, more energy-efficient solution that leverages existing global infrastructure, reducing logistical complexity.

“This collaboration is a true game-changer for global agriculture and hydrogen transport. By combining our advanced technology with the groundbreaking innovation of Professor Torrente at the University of Cambridge, we are not just providing a highly decarbonising solution; we are powering a fantastic green future for the world's farmers and vital hydrogen infrastructure.”

Core initiatives of the collaboration

Paragon will focus on scaling up the production of certified green ammonia, with initial plants set to start full production by Q2 2026. The core initiatives include:

- Scaling Certified Production: Deploying systems to generate high-volume, high-quality hydrogen feedstock from end-of-waste aluminium, enabling the production of over 20 tonnes per day of certified green ammonia per plant.

- Reducing Emissions and Costs: Deploying new, state-of-the-art modular processing units strategically located near industrial hubs to drastically cut transport costs and associated emissions.

- Decarbonising Key Sectors: Delivering certified green ammonia for reuse in high-performance fertiliser and chemical applications, offering a viable alternative to the UK’s current reliance on high carbon ‘grey’ ammonia.

- Optimised Hydrogen Logistics: Utilising green ammonia as a stable, high-density carrier to facilitate the safer and more efficient transport of larger hydrogen volumes over long distances.

Leading the UK’s Green Charge

“Providing new green ammonia synthesis technologies for efficient, modular, distributed manufacturing is an essential part of the decarbonisation roadmap” said Professor Torrente. “We are glad to partner with local, UK-based innovators to make real impact towards green fertilisers and fuels”.

“We are excited to see this technology take a step forward to making an impact on the climate crisis. Ammonia synthesis hasn’t changed in over a century and this innovation has the potential to disrupt this established process and significantly decrease carbon emissions.”

The inaugural facility is set to launch at the renowned Westcott Venture Park, with ambitious plans to expand operations nationwide over the next 24 months.

Image credits: Unsplash

For Media Enquiries, please contact:

Communications – Paragon Resources

M: +44 (0) 7800 991909

E: helen.aletra@paragonresources.uk

W: www.paragonresources.uk

Cambridge Enterprise

Cambridge Enterprise www.enterprise.cam.ac.uk/contact