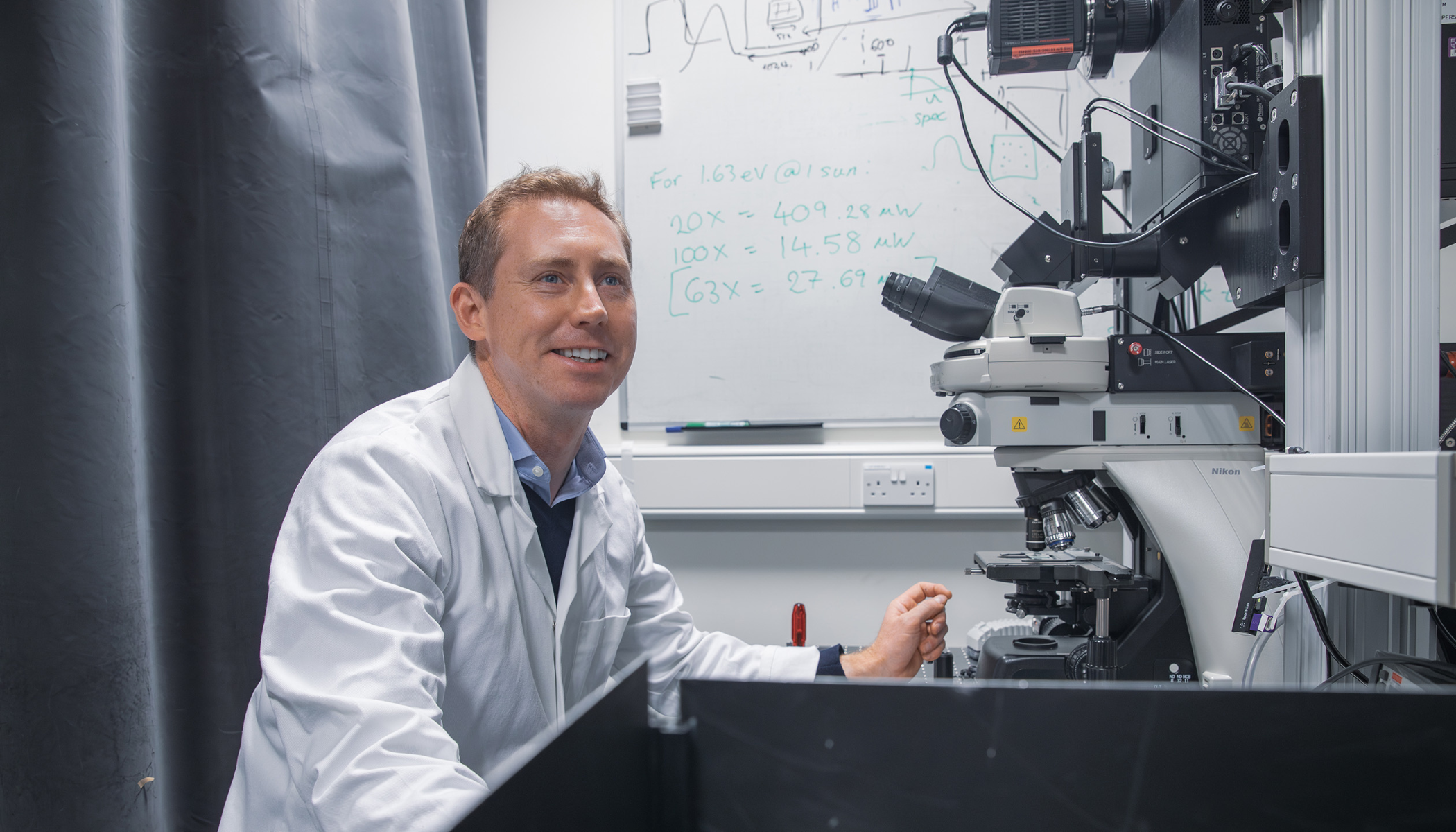

The printed plastic photovoltaic technology developed by Cambridge Enterprise portfolio company Eight19 could help keep the lights on for those living off the grid in developing countries.

As one of the panel members at Economist Conference’s UK Energy Summit, held last week in London, Eight19 CEO Simon Bransfield Garth described how the company’s printed plastic photovoltaic (PV) cells could conceivably cover the football pitch at Wembley Stadium using just one kilogram of material.

As many key manufacturing materials are in increasingly short supply, the ability to manufacture more using less will be crucial to the future of the solar industry. Bransfield Garth highlighted the need for replacing conventional, energy-intensive manufacturing techniques with advanced printing and coating processes, similar to those being pioneered by Eight19’s printed plastic PV, in order to maximise carbon reductions.

Our roll-to-roll manufacturing processes will vastly reduce the cost of production making future solar more affordable and accessible for those currently living off-grid.

Bransfield Garth

Nanotechnology such as Printed PV could also play a key future role in providing a clean and renewable solution to the energy deficit in fast growing countries such as India, where there is currently about a 12% peak energy deficit.

For example, the peak energy gap in India is set to grow as average electricity consumption doubles over the next five years. Much of the gap is currently filled by expensive and polluting local diesel generation, which has a significant impact both on carbon footprint and, because most is imported, future energy security.

In India, as with a number of emerging economies, the high cost of energy and limited infrastructure is spurring a dramatic rise in so called ‘off-grid’ renewables, where people generate the electricity they need locally.

“Eight19’s flexible, printed plastic solar cells can be used to charge devices such as lanterns and mobile phones, helping replace these fossil fuels with clean, cheap and renewable energy that stimulate education, commerce and the pace of development where they are deployed,” Bransfield Garth said. “Our roll-to-roll manufacturing processes will vastly reduce the cost of production making future solar more affordable and accessible for those currently living off-grid.”

Tags: bransfield garth, Eight19, energy, nanotechnology, Photovoltaic, solar