As far as packaging materials go, plastic-aluminium laminates are great. They’re light, they’re cheap and they use fewer raw materials than many other forms of packaging. Their major drawback, however, is that they cannot currently be recycled.

Cambridge Enterprise portfolio company Enval Limited has come up with a solution, however. They have developed a patented process which offers a genuine recycling route for flexible laminate packaging, a process which is economically and environmentally viable and diverts waste from landfill.

The margins in environmental services are very small, and there is little taste for environmental processes which are expensive. That is why we have tried to make our process as cost-efficient as possible.

Carlos Ludlow-Palafox

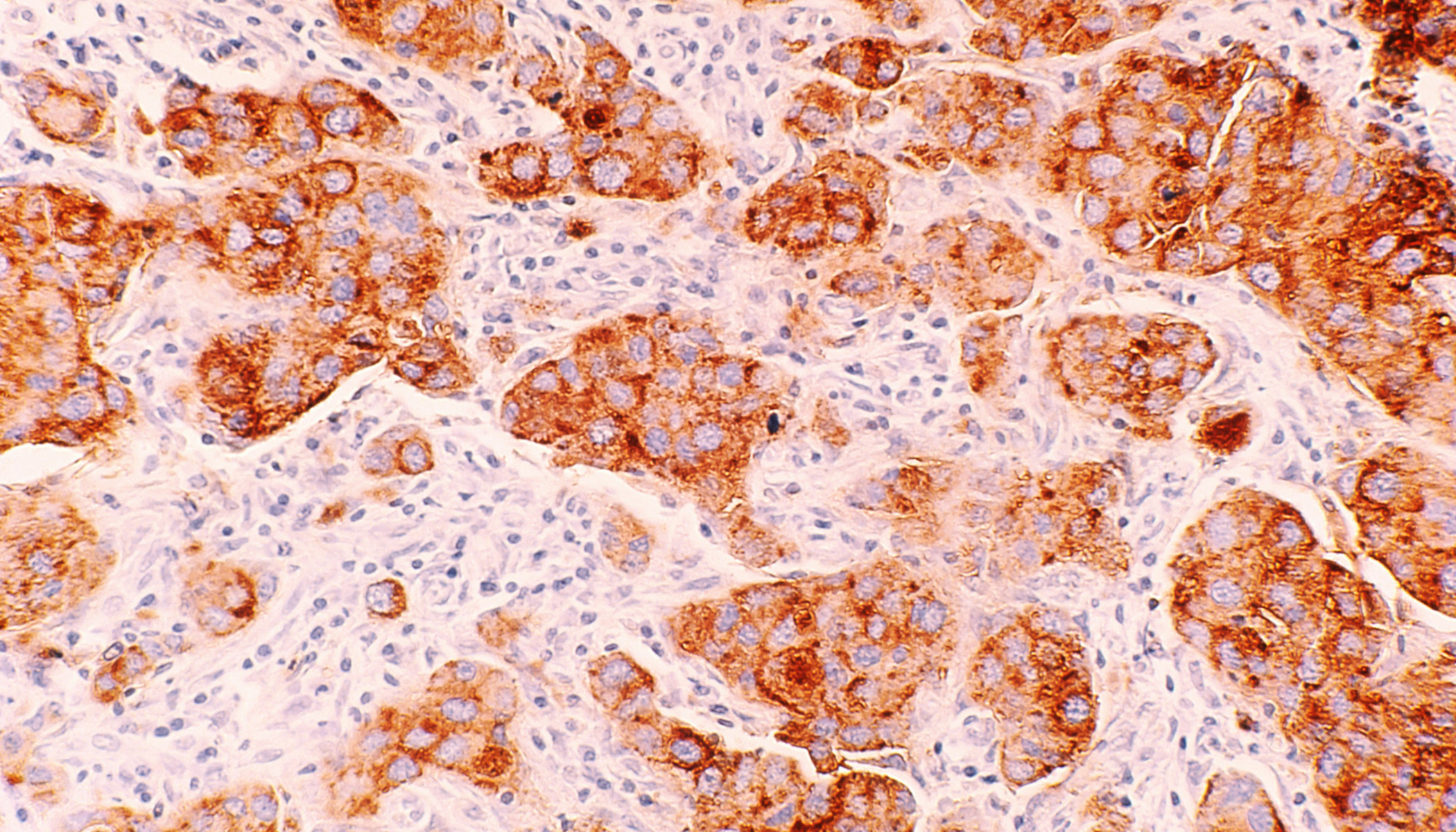

Many types of packaging such as toothpaste tubes, coffee pouches, pet food bags and drink cartons, are primarily composed of plastic-aluminium laminate, which is not conventionally recyclable. The process developed by Enval uses microwaves to break down the plastic-aluminium laminate. The laminate is heated up in the absence of oxygen, preventing it from burning. When a high enough temperature is reached, the plastic in the packaging will begin to break down, separating it from the aluminium. What remains is clean aluminium ready for introduction into the secondary aluminium supply chain, and hydrocarbons that can be used as fuel or chemical feedstock.

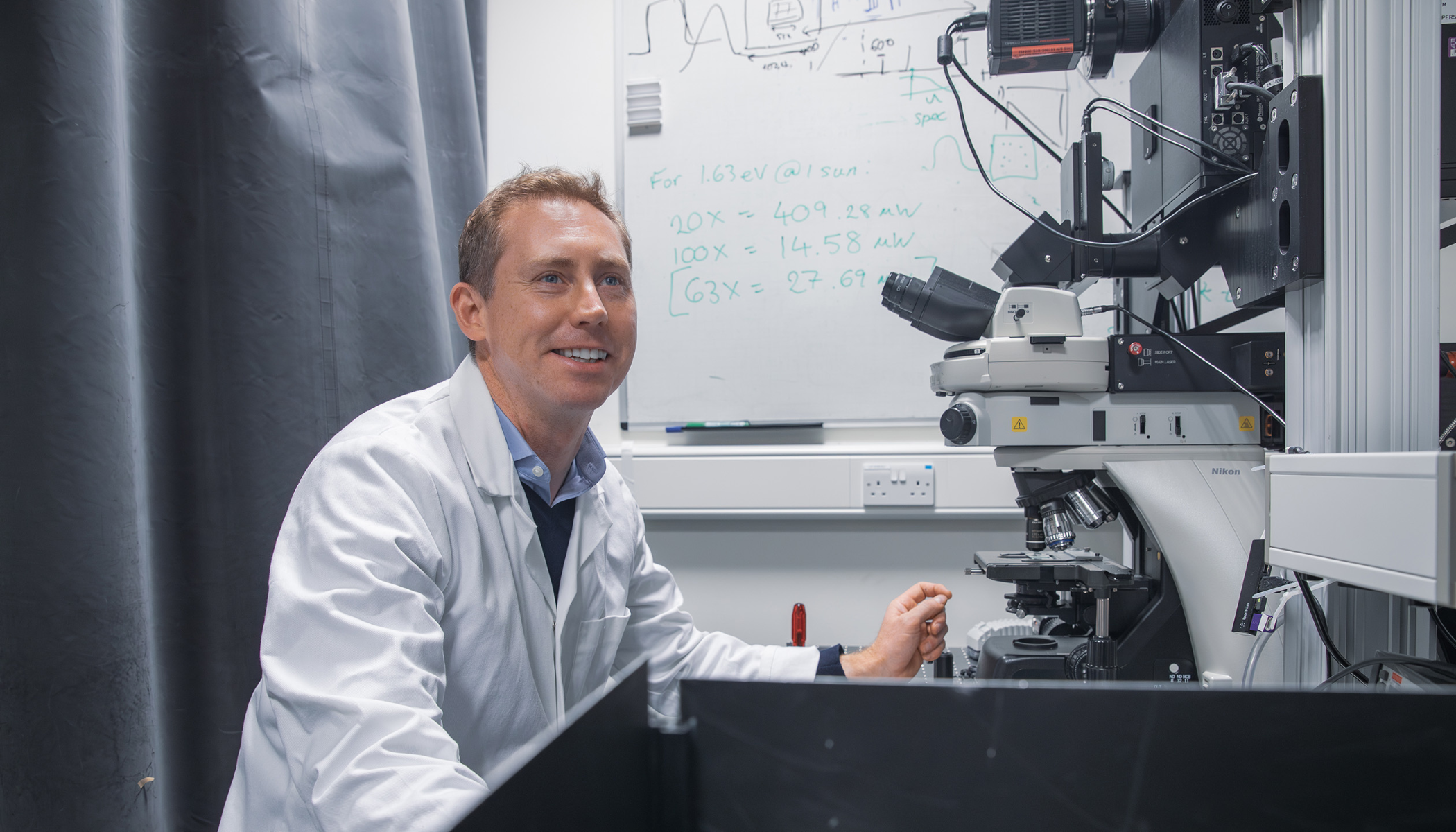

Enval’s beginnings date back to 1997, when Carlos Ludlow-Palafox arrived in Cambridge as a PhD student in the Department of Engineering, where he helped develop the foundations of the Enval process under the supervision of Professor Howard Chase.

In 1999, Prof Chase received funding from the Engineering and Physical Sciences Research Council (EPSRC), which enabled him to start matching his recycling method with non-recyclable materials, such as medical blister packs and drink cartons. Following the completion of his PhD, he was offered a postdoctoral position at Cambridge, and began attempting to commercialise his research.

At a funding pitch to Cambridge Capital Group (CCG), Carlos was introduced to Martin Lamb, a business angel with a background in semiconductor materials, who eventually became Chairman of Enval. Martin says he was taken by the technology which Carlos had developed. “I liked that it was a straightforward process, and I did buy the idea that the process would work with many units spread over many different locations, rather than one centralised facility,” he says.

Martin says he was also personally impressed by Carlos. “He has such a well-rounded skill set. The most difficult thing you deal with in business is people, not technology,” he says. “It is rare to find people who can effectively deal with both, and Carlos is one of those people. There are lots of good ideas around; but in business you need the combination of good ideas with good people in order to succeed.”

In 2005, they received Proof of Concept Funding from Cambridge Enterprise Seed Funds in order to further develop their recycling process. “The Proof of Concept funding made a massive difference in the development of our recycling process, as it gave us valuable leverage” says Carlos.

Later that year, Howard and Carlos (together with Dr Alex Domin) won the Cambridge University Entrepreneurs’ Business Creation Competition, founded Enval Ltd and, following the construction of the first bench scale prototype of the process, received in 2006 a significant investment from a syndicate of investors.

In 2007 Enval received a Research Grant from the East of England Development Agency that allowed the company to continue the development of its technology for different applications, and in 2008 the successful completion of the first pilot-plant of the process led to completion of a funding round in 2009.

“The margins in environmental services are very small, and there is little taste for environmental processes which are expensive,” Carlos says. “That is why we have tried to make our process as cost-efficient as possible.”

Tests with the pilot-plant that Enval has carried out over the last 12 months have shown that the process can be used to address the challenges presented by laminate materials. The Enval process now allows packaging systems based on these materials, such as aseptic drink cartons, food pouches and toothpaste tubes, to be completely recycled in a sustainable and economically viable way.

Photo credit: Nespresso expands aluminium recycling and reuse by Nestle via Flickr