Aurelius Environmental, part of Aurelius Holdings, and Dr Vasant Kumar from the Department of Materials Science and Metallurgy, have together secured a grant of over £465,000 from Innovate UK to develop Brazil's sustainable urban environments. Their partner in Brazil, recycling company Antares Reciclagem, secured over £210,000 as part of the same bid.

The UK–Brazil Newton Fund is co-financed by Innovate UK and the Brazilian government. One of the key aims of this initiative is to address “the reality of climate change and dwindling natural resources” by delivering efficient and environmentally-friendly solutions for the generation and storage of energy, and the treatment of their associated waste streams.

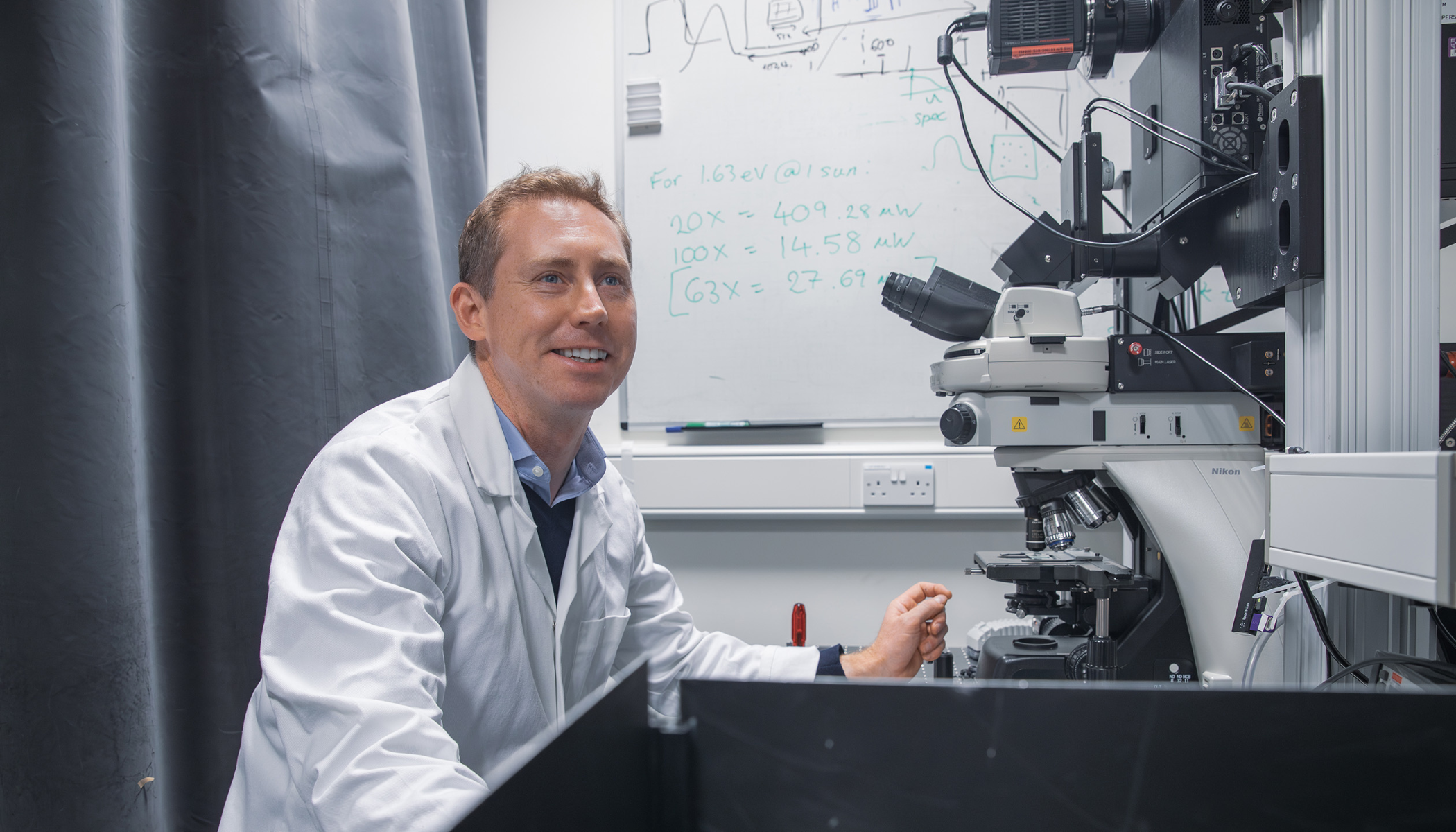

The partnership between Aurelius and the University of Cambridge started in 2016, with Cambridge Enterprise licensing exclusively to Aurelius a technology for the processing of lead-acid battery paste. The paste is the main active component of the lead-acid battery, and contains a mixture of lead-based salts. Since 2016, Aurelius has been scaling up and piloting the process with support from Dr Kumar.

Dr Athan Fox (Technology Director at Aurelius) said: “The global lead-acid battery market is forecast to reach $84 billion USD by 2025. This is driven largely by expansion of the automotive industry in developing countries, including Brazil. More batteries on the road means an ever-increasing amount of battery waste, so our process for the recycling of lead-acid battery paste could not be more timely. The Innovate UK Newton Fund is allowing academia and industry to join forces, taking Brazil and the UK a step closer to clean, economic and sustainable recycling of lead-acid battery waste”.

Treating battery paste with this hydrometallurgical process reduces its carbon footprint by over 80% compared to treatment with the pyrometallurgical process—the incumbent industry. The hydrometallurgical process developed by Aurelius also eliminates noxious gases such as sulphur dioxide and nitrogen dioxide without having to deploy gas abatement technologies.

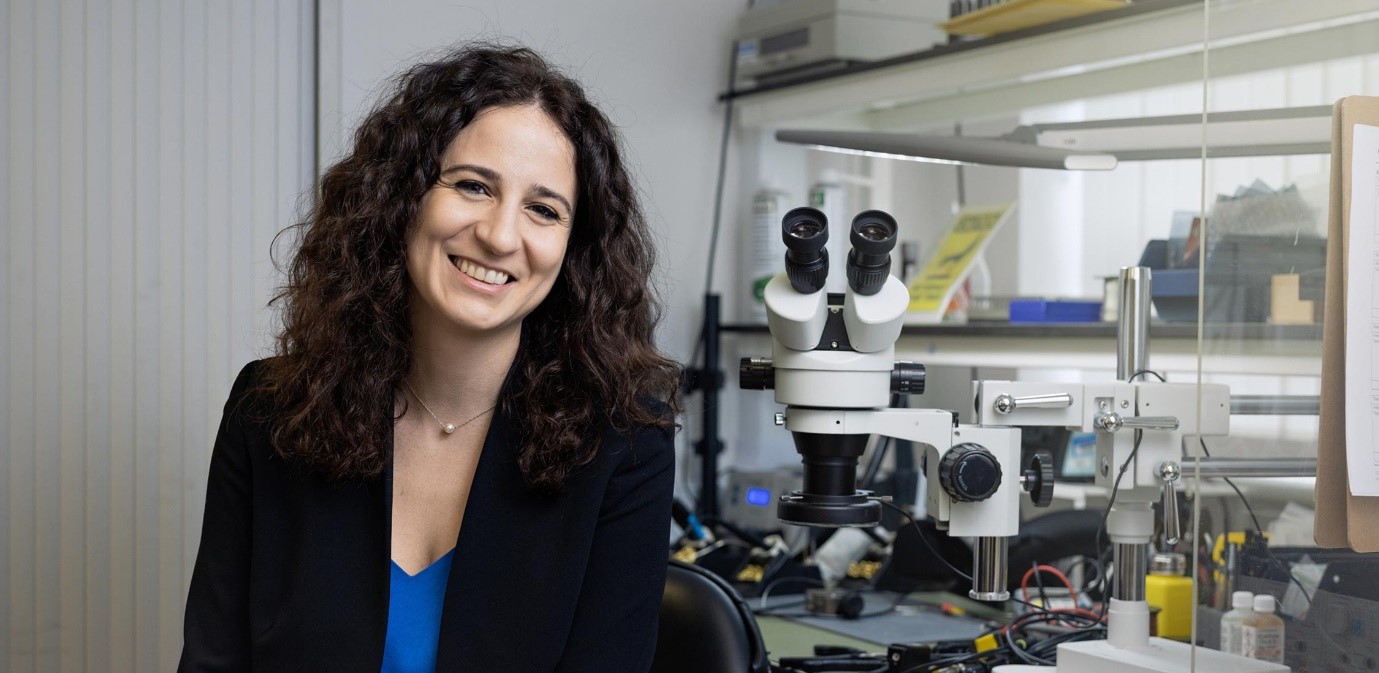

Aurelius and the University of Cambridge are teaming up with Antares Reciclagem, specialists in the treatment of waste battery acid, and Tudor Batteries, a lead-acid battery manufacturer, both in Brazil. Antares have developed and commercialised a process for cleaning waste battery acid and re-using it in other industries, including the pulp and paper industry.

Almir Trindade (Chief Executive Officer at Antares) said: “By recycling the waste battery acid we completely avoid neutralisation, saving 85 kg of carbon dioxide for every tonne of electrolyte treated. Our process is not only green, but also saves money. This is why about 80% of Brazilian lead smelters now use our technology”.

Miles Freeman (Chief Executive Officer at Aurelius) said: “There is a great opportunity to combine the technological achievements of Aurelius and Antares to deliver cleaner, more economic and sustainable recycling for lead-acid batteries. Our ability to develop sustainable urban environments is boosted by collaboration between industry and academia, and by collaborating across disciplines and continents. Indeed, our aim is to deliver the Antares acid-recycling process to the UK and European markets, while simultaneously bringing the Aurelius paste-treatment technology to Brazil with the help of Innovate UK’s Newton Fund and the University of Cambridge”.