The commercialisation of advanced materials has always been challenging due to the steep costs and risks involved.

Progress on moving a new material toward market can too often be followed by reversal, like a real life game of Snakes and Ladders.

The annual Materials Research Exchange conference brings people tackling these challenges together to share insights and successful tactics. Cambridge Enterprise used MRE2020, which was held in London in February, to showcase three of our portfolio companies that have successfully joined the game.

Materials Research Exchange, which is organised by the Knowledge Transfer Network, connects British university research groups and industry research centres working on advanced materials, with around 1500 delegates attending. The sheer range of materials innovation presented at this year’s conference was staggering!

University of Cambridge showcase

We attended the conference along with representatives from The Henry Royce Institute, the UK’s national institute for materials science research and innovation, consisting of a partnership between the universities of Cambridge, Imperial, Oxford, Sheffield, Manchester, Liverpool, and Leeds plus the National Nuclear Laboratory and UK Atomic Energy Authority. Cambridge Royce, based in the University’s Maxwell Centre, focuses on Materials for the Energy Transition. Key research areas are materials for energy generation, energy storage, and efficient and sustainable energy use.

The Cambridge Royce has fifteen advanced materials growth and characterisation facilities that are available for use by academic and industrial researchers. Please contact Lata Sahonta or Andrew Dobrzanski for more information on the Royce facilities.

The three portfolio companies that we showcased at Materials Research Exchange 2020 are:

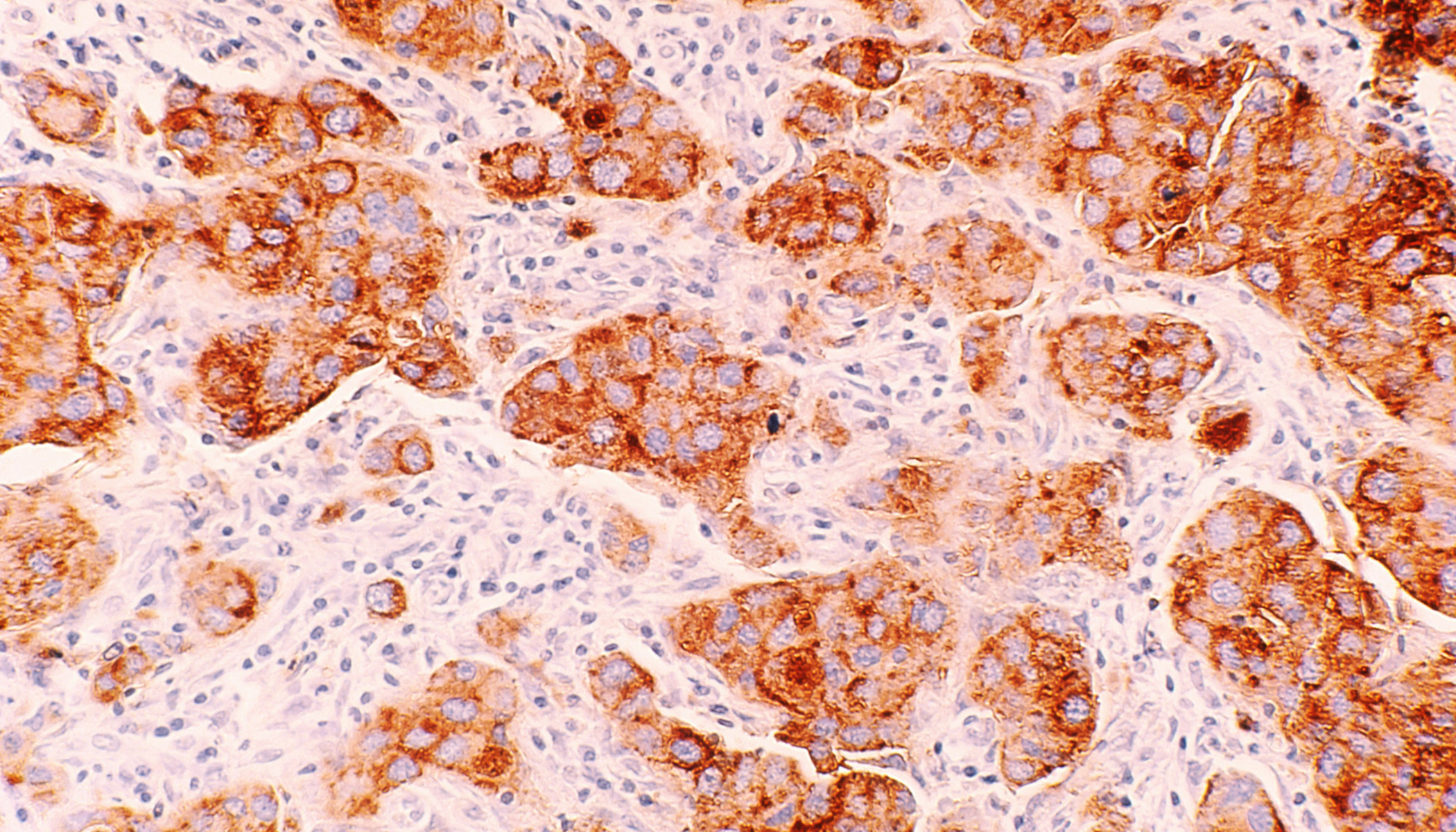

| Xampla | The technology was developed in Professor Tuomas Knowles’ group, in the Department of Chemistry. Plastic pollution is having a significant detrimental effect on our planet. Founded in 2018, Xampla has a highly innovative solution – a natural plastic alternative made entirely from plant protein that is biodegradable and biocompatible. The technology can make microcapsules, beads, coatings, threads and other structures and materials, including films and packaging. |

| Cambridge Photon Technology | Cambridge Photon Technology is developing a Photon Multiplier Film (PMF) to increase the power output of solar panels by as much as 20%. Solar manufacturers urgently need new solutions to improve the performance of their products, since standard silicon technology is approaching its practical limits. PMF will meet this need by providing a dramatic boost in power, while integrating with existing silicon module designs and manufacturing processes for ease of adoption. The company was founded in 2019, and works closely with the inventors of PMF technology at the Cavendish Laboratory and Department of Chemistry. |

| Barocal | The technology arises from Dr Xavier Moya’s lab in the Department of Materials Science & Metallurgy Refrigeration and air conditioning currently devour over 15% of the electricity produced worldwide, and contribute over 6% of Global Greenhouse gases. Demand for cooling is only going up. Founded in 2019, Barocal are developing solid-state cooling technologies where cooling occurs by applying and removing pressure to barocaloric organic solids, which leads to temperature changes of the system. Solid state cooling has the potential to be much more efficient than traditional vapour compression technology. As a finalist of the Global Cooling Prize, Barocal are working towards a demonstrator prototype. |

Industry discussion

MRE2020 included a range of talks and sessions, covering many aspects of materials commercialisation. Several speakers highlighted the need for careful consideration of sustainability and environmental impact when developing new materials. End-of-life processes and the circular economy were mentioned several times. While there was a key focus on plastics and plastic waste, this session showed the importance of treating all materials as the precious resources they are.

Materials Design Exchange (MaDE) also ran a session where several artists showcased their research and spoke of their experiences in pushing the boundaries of existing materials, with interesting similarities to the work carried out by scientists and engineers. I was particularly delighted to see Les Bicknell’s Unfolded Thinking project presented during this session—which I had the privilege of participating in during my PhD at Cambridge.

Materials commercialisation has always been challenging due to the time, expense, and risk involved in taking a material from the lab, through scale-up, customer testing and regulatory approval, and finally to market. In addition to the technical hurdles, there are considerations regarding the human factor, usability, real world testing, and using the feedback from testing to inform and direct product development. Furthermore, adoption of new materials also involves re-educating end users about the new material.

One of the speakers used a great “snakes and ladders” analogy to describe materials commercialisation. Work progresses in materials development, then suddenly hits a hurdle and progress is put a few steps back. There need to be more aids to accelerate the development process, helping advanced materials move up the ladder.

There are several excellent initiatives from UK Research & Innovation (UKRI) to support materials innovation by investing in people, projects, and infrastructure. Working collaboratively in meaningful product partnerships was also discussed intensively, with several case studies presented. One important take-home from this is that connecting industry problems and solution providers is vital to ensuring that we are solving the right problems.

Conference takeaway

It was apparent from attending MRE2020 that we are all facing similar challenges in commercialising advanced materials. It was also clear that there is tremendous passion and enthusiasm within the community to see materials innovation making a difference and benefiting society.

Cambridge Enterprise will continue to look for new approaches to support materials innovation and commercialisation by facilitating meaningful collaborations, championing ground–breaking projects, and empowering our academics to take their cutting-edge research out into the wider world. If you are a University academic working on an exciting new material and are interested in exploring how it could be commercialised, or a company interested in learning about the cutting-edge materials research at here, then please talk to us.