Sustainability in the manufacturing industry has become a critical success factor for reaching net-zero goals.

Combatting global climate change requires urgency, scale, and high ambition. This involves overcoming the often complex language and calculations required for environmental improvements. Despite the immense potential for enhancing eco-friendly practices, aligning these efforts with daily management processes and leadership objectives can be challenging.

Developed by Gary Punter, Ian Bamford, and Steve Evans at the Institute for Manufacturing (IfM), a division of the University of Cambridge’s Department of Engineering, the Cambridge Sustainability Improvement Method (CSIM) is an 8-step organisational engagement programme designed to transform factories sustainably.

Also known as Sustain8, this methodology ensures sustainable alignment by providing a foundation for improvement through the engagement of front-line factory workers. It offers a structured, cost-effective approach to increasing sustainability in manufacturing plants, which is an important area in the fight to tackle climate change. By analysing factory data, CSIM identifies key operational drivers and guides factories in selecting areas where sustainability aligns with business success. With results in 12 months, the method engages the workforce in finding and running simple in-house projects, achieving a 15-30% improvement in energy, waste, materials, water, and rework efficiencies.

“The method takes a pragmatic approach designed to work with instead of against how the factory is run and enables the discovery of sustainability wins, which are unique in each factory setting.”

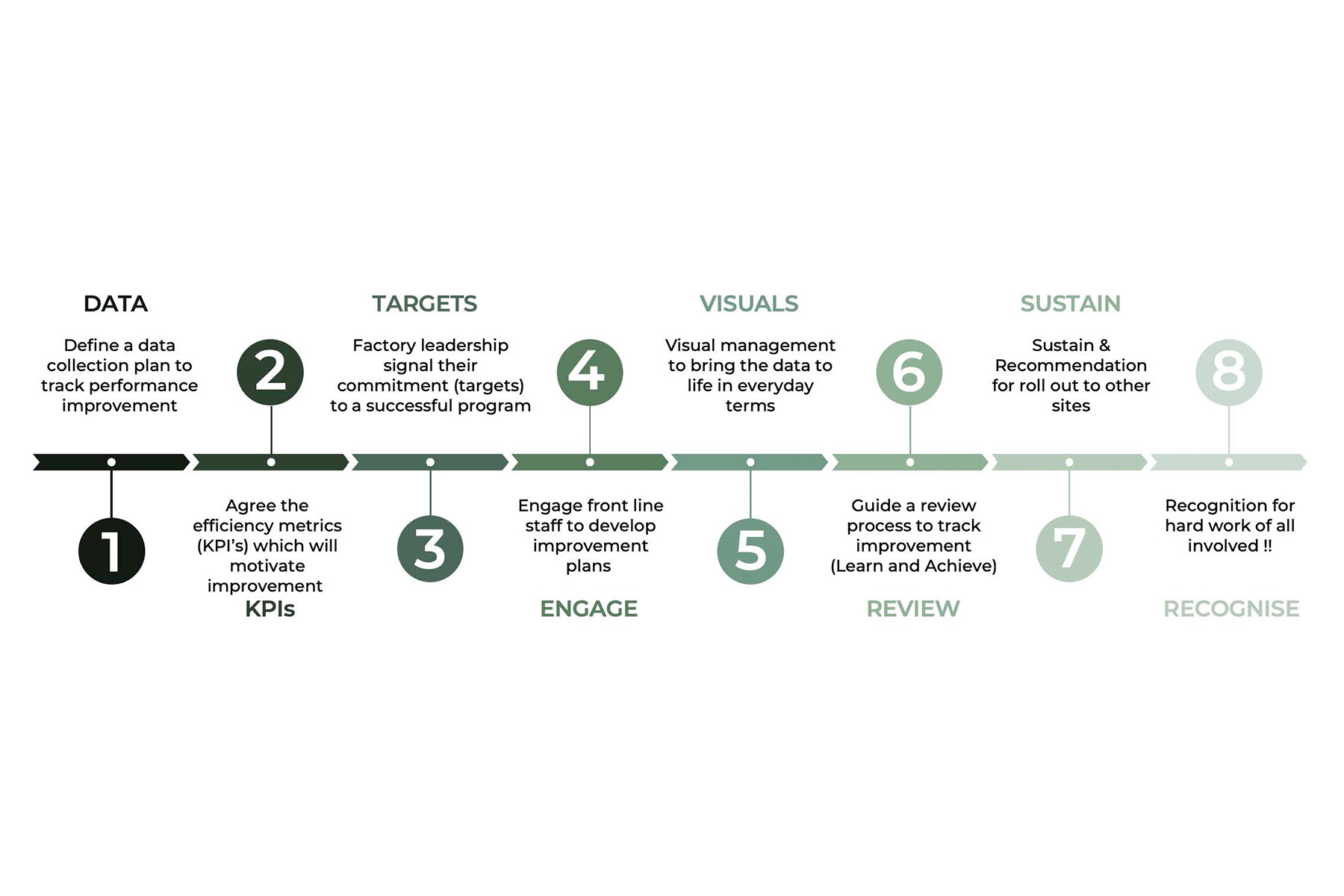

Eight steps to sustainable, continuous business improvement

The Cambridge Sustainability Improvement Method (CSIM) is focused on making significant sustainability improvements with minimal investment. By bridging the gap between corporate objectives and sustainable practices on the factory floor, this approach has been successfully implemented in numerous factories, yielding measurable savings within just one year of implementation.

Gary Punter, a visiting Fellow at the Centre for Industrial Sustainability and a consultant for IfM Engage, Ian Bamford, Commercial Director at the University of Cambridge’s UK Centre for Industrial Sustainability, and Professor Steve Evans, Director of Research in Industrial Sustainability at the Institute for Manufacturing, created this methodology to fill the gap and inspire frontline staff to build improvement plans that resonate with their day-to-day activities.

“By focusing on the strengths of factories on their best days, we can identify what sets them apart and replicate these practices more frequently. This leads to significant sustainability improvements. We have witnessed the positive and motivating impact of this approach.”

– Gary Punter, Industrial Associate, IfM Engage

The eight steps of CSIM

The initial steps of its scalable process focus on establishing a robust data collection plan, baselines and effective KPIs to drive improvement. Within four months, improvement teams are set up and working on action plans throughout the factory. Across diverse cultures and sectors, notable KPI improvements have been achieved within a year.

People powered sustainable transformation

CSIM is supported by comprehensive training documentation and is available for licensing through Cambridge Enterprise. The CSIM handbook is designed to provide companies with the methodology to engage their front-line factory staff. It is particularly aimed at brands or conglomerates that want to create their own internal transformation teams to run sustainability programmes in their or their suppliers’ factories.

Dr Siân Fogden, adds: “CSIM has been a brilliant addition to the Research Tools portfolio at Cambridge Enterprise. It’s clear ability to enhance factory sustainability using a method developed out of an understanding of the importance of working with not only the factory management but also those people working day to day on the factory floor.”

Image Credits: CSIM, Freepik