Concrete is essential to our built environment. We use over four tonnes of it every year for every person alive on the planet.

However, cement, which is used to bind concrete, contributes 7.5% of global carbon emissions – triple that of aviation.

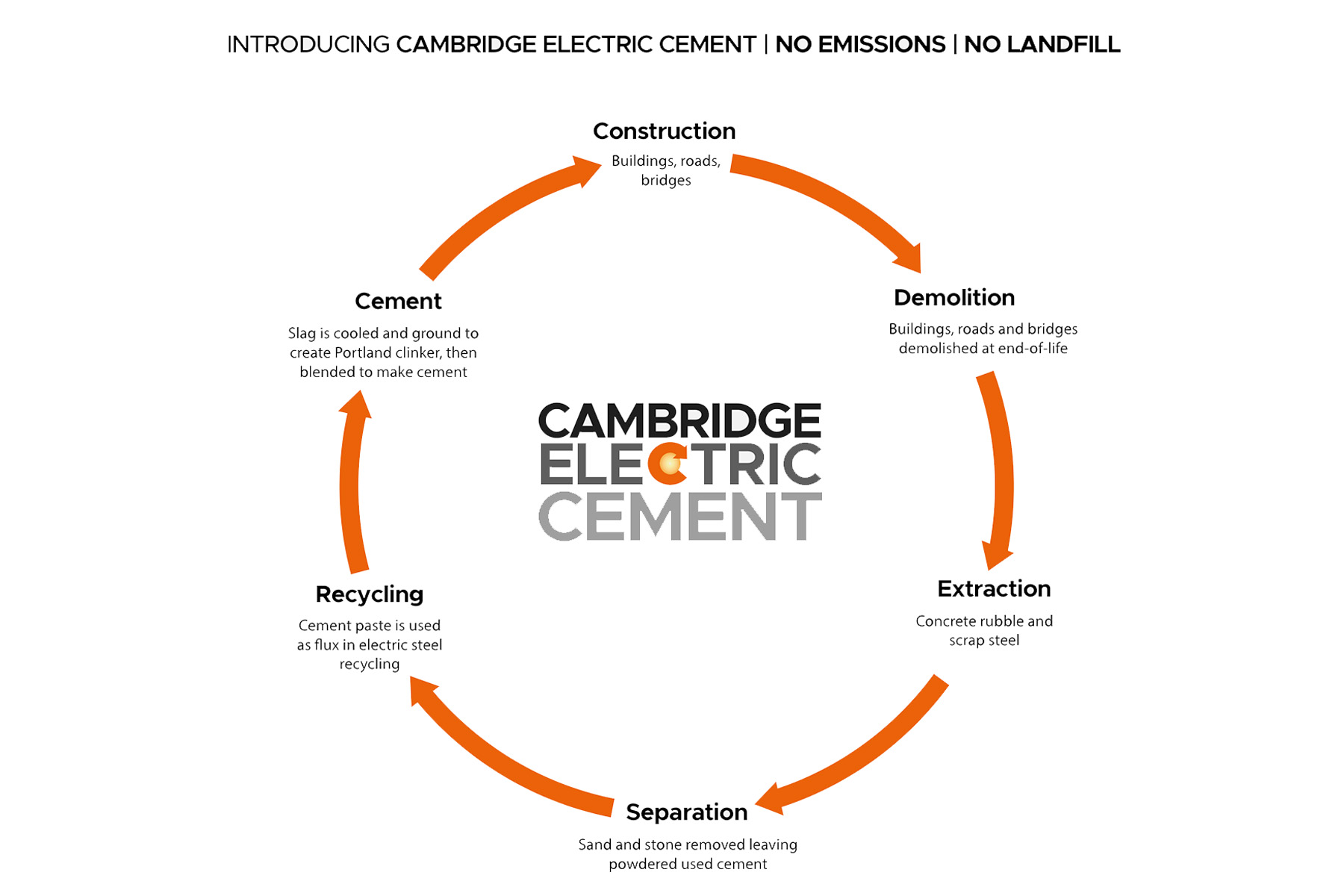

Cambridge Electric Cement (CEC) has developed a technology for recycling cement from demolition waste, making zero-carbon cement a possibility. It does this by replacing the lime flux used in steel recycling with recovered cement paste, producing a clinker that can be used to make new cement, without affecting the steelmaking.

The performance of this recycled cement can match that of Portland cement (the cement most commonly used to make concrete) without the environmental impact.

“People have always known you could recycle cement. In principle, it’s got all the right ingredients to make cement. But there is no cement to recycle, only concrete, which is 80% rock and only 20% cement.”

Scaling recycled cement solutions with CEC’s partner network

A spinout from the University of Cambridge, CEC has developed the world’s first process for making low-carbon, recycled cement by processing it through the same electric arc furnaces (EAFs) used in steel recycling. This innovative process does not affect steelmaking and produces virgin cement.

Founded in 2022, CEC’s research, led by academic co-founders Professor Julian Allwood, Dr Cyrille Dunant, and Dr Pippa Horton, is now collaborating with an established industry partner network – including AtkinsRéalis, Balfour Beatty, CELSA UK, Day Group, Materials Processing Institute, and Tarmac – on the ‘Cement 2 Zero’ industrial demonstrator project. This project aims to certify and commercialise the product, initially targeting low-risk, non-structural construction applications.

The team’s scientific research continues at the University of Cambridge, as well as with research teams at the University of Warwick and Imperial College, led by Zushu Li and Rupert Myers. This work is supported by £2m in funding from the Engineering and Physical Sciences Research Council (EPSRC).

In July 2024, CEC secured £2.25m in pre-seed funding, led by decarbonisation-focused Zero Carbon Capital, with participation from existing investors Legal & General, Cambridge Enterprise Ventures, Parkwalk Advisors, Delph25, and Almanac Ventures.

CEC already has 75,000 tonne trials with industrial partners underway to scale the technology.

“Decarbonising cement is one of the world’s most difficult challenges. Cambridge Electric Cement produces a true zero-emission cement with the potential to save gigatonnes of carbon. This is a huge step forward for our planet, made possible by the partnership of great science and founders from the University of Cambridge and Cambridge Enterprise.”

Chris Gibbs, Investment Director (Physical Sciences), Cambridge Enterprise

As the 16th company in our sustainability portfolio, CEC takes the total investment in this portfolio since August 2020 to over £7 million.

Image Credits: CEC, Unsplash