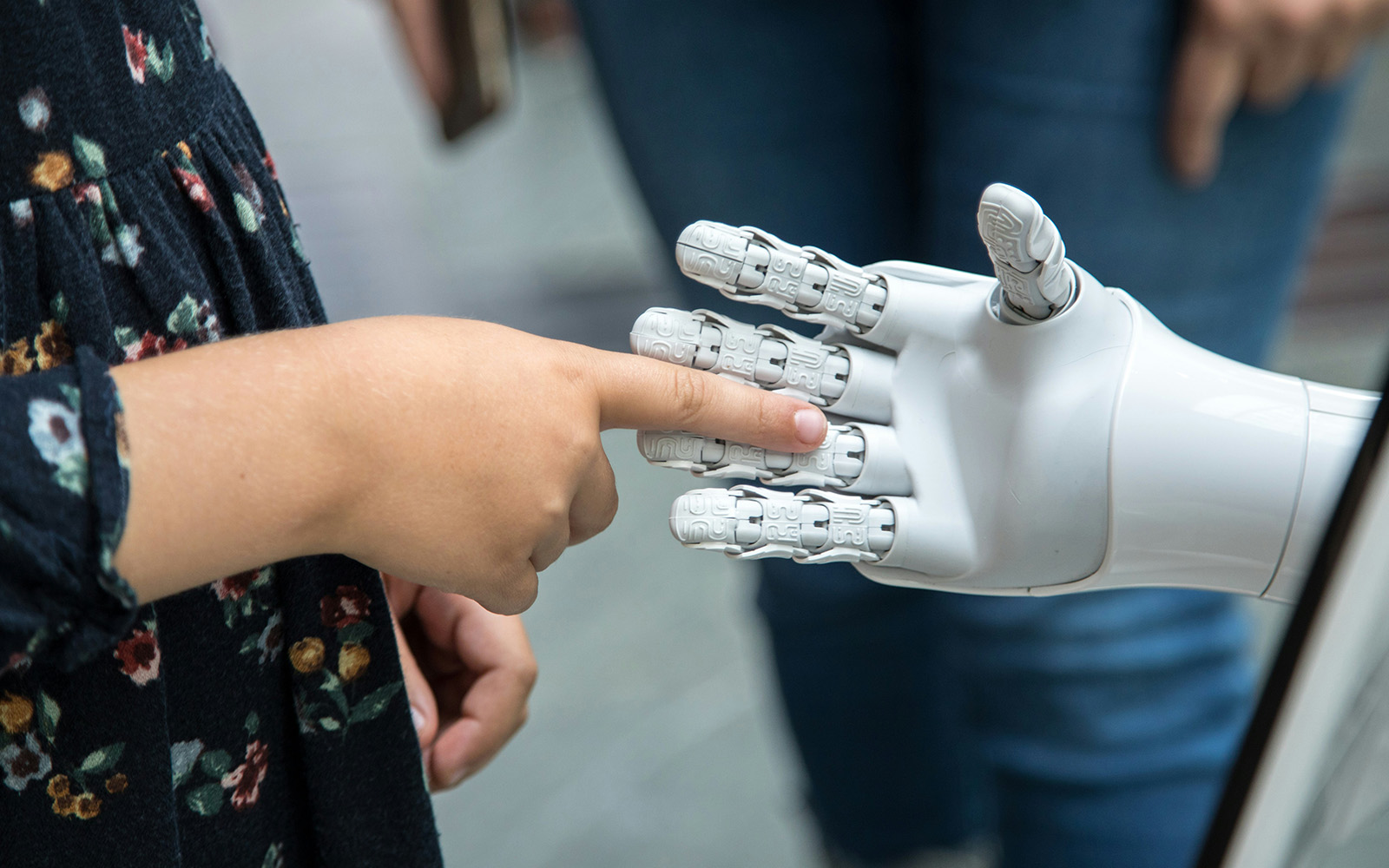

An innovative composite mimics human skin

This innovative composite e-skin is a soft, pyramid-patterned pressure and force sensor that emulates the multidimensional touch sensitivity of a human fingertip.

It delivers high sensitivity, a broad range and real-time vector (normal and shear) read-out plus slip/roughness flags in a single patch.

This product targets developers of prosthetics, industrial and agricultural manipulators, soft robots, and any human-machine interface creators who are frustrated with the limitations of current one-axis, narrow-window tactile pads. By providing machines with human-grade tactile feedback, this technology eliminates dead zones, expands the operational envelope, and enables self-adjusting grips, safer handling, and richer tactile responses. The performance is measured to be 10–100 times better than existing products.

Background

Developed by Professor Hasan, this innovative tactile sensing technology combines innovative fillers within a flexible composite structure to deliver high-sensitivity, multidimensional force detection. Inspired by the layered architecture of human skin, the sensor features anisotropic particle networks, microporous layers, and a pyramid-patterned surface that enhances its ability to detect and differentiate normal and tangential forces. With a pressure sensitivity of 110 kPa⁻¹ across a wide dynamic range of 500 kPa. Crucially, it can decouple force components to enable accurate 3D force recognition, slip detection, and surface roughness sensing.

Technology overview

This compact 3D force sensor integrates a MEMS piezoresistive chip with a soft elastomeric cap featuring pyramid-shaped microstructures that enhance force transmission. Stress-concentrating microholes in the cantilevers enable precise detection of normal and tangential forces with low hysteresis and fast response. A neural network processes the sensor’s output to accurately reconstruct 3D force vectors in real time.

Benefits

- High Sensitivity Across All Axes: The sensor design enables precise detection of forces in three dimensions (X, Y, Z), with enhanced sensitivity due to stress-concentrating microholes and pyramid-shaped surface structures.

- Low Hysteresis and Fast Response: The sensor exhibits minimal hysteresis (<1.91%) and rapid response times (~30 ms), making it suitable for real-time applications requiring accurate force feedback.

- Compact and Scalable Design: Its small footprint and MEMS-based architecture allow for easy integration into compact systems, including surgical tools and robotic grippers.

- Neural Network-Based Signal Decoupling: Advanced signal processing using artificial neural networks enables accurate decoupling of normal and tangential forces, improving the reliability of 3D force reconstruction.

- Slip and Texture Detection: The sensor can detect slip events and surface roughness, enhancing its utility in tasks requiring fine tactile discrimination.

Applications

- Automated manufacturing: enhances the precision and reliability of automated handling systems.

- Soft robotics: mimics the sensing capabilities of human fingers.

- Healthcare: potential applications in prosthetics for better force feedback and control.