CamGaN, a University of Cambridge spin-out in the area of high-brightness light-emitting diodes (HB-LEDs), has been acquired by Plessey, a semiconductor manufacturer based in Plymouth.

CamGaN was formed in 2010 to commercialise a novel technology for the cost-effective manufacture of key components of HB-LEDs. This novel technology holds strong potential to dramatically reduce the cost of solid-state lighting devices that are expected to replace incandescent and fluorescent light bulbs.

Solid-state lighting devices based on HB-LEDs are extremely energy efficient, and can reduce the amount of electricity used to light households, businesses and public spaces by over 90%. A recent report estimates that 46% of the world’s lighting fixtures will be converted to solid-state devices by 2020, resulting in an estimated $489 billion in energy savings. However, HB-LEDs are currently prohibitively expensive to manufacture, making the retail price of these new devices too high for widespread uptake.

This technology provides Plessey with a significant commercial breakthrough in a rapidly emerging industry.

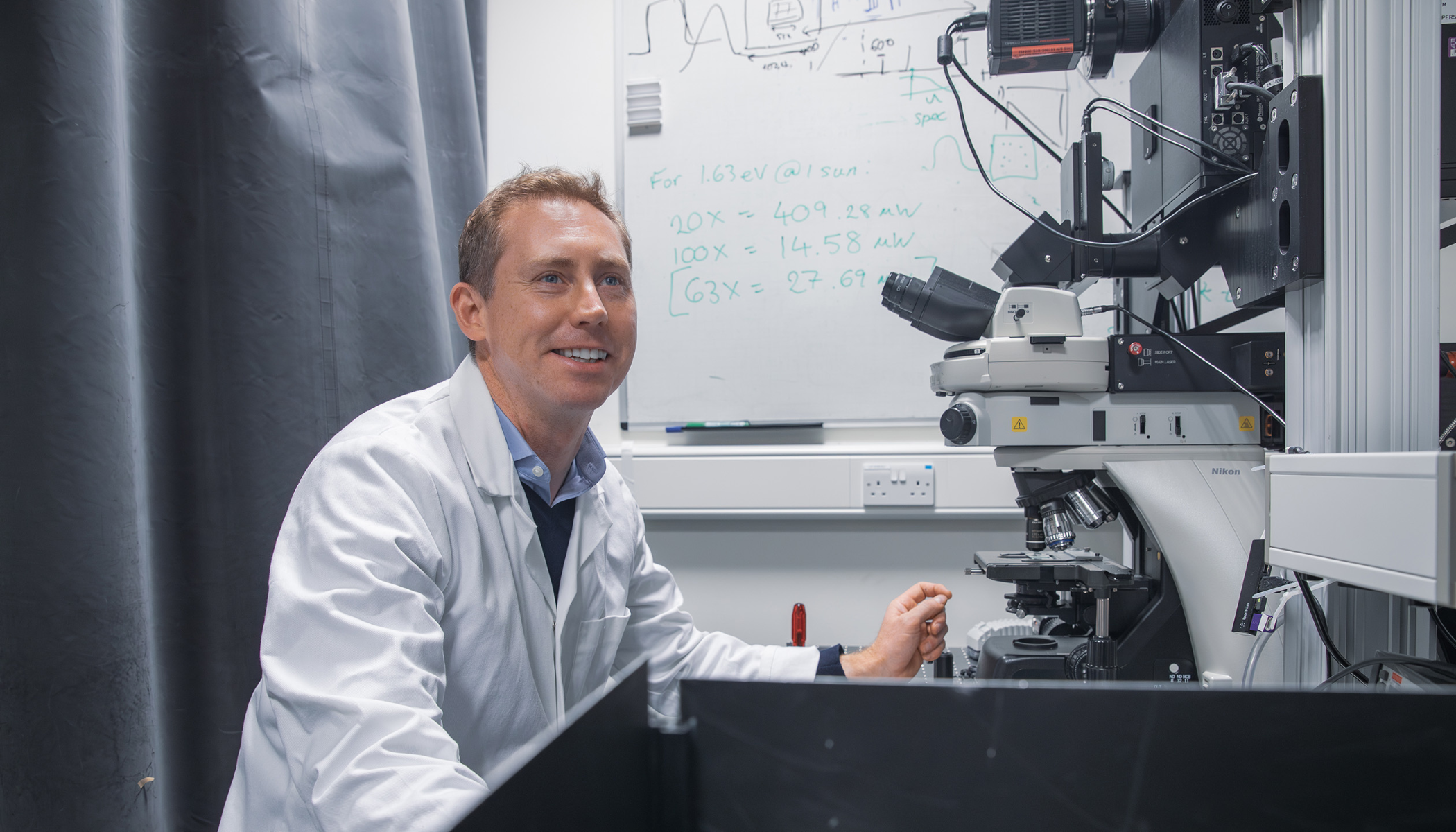

Dr Andrew Lynn

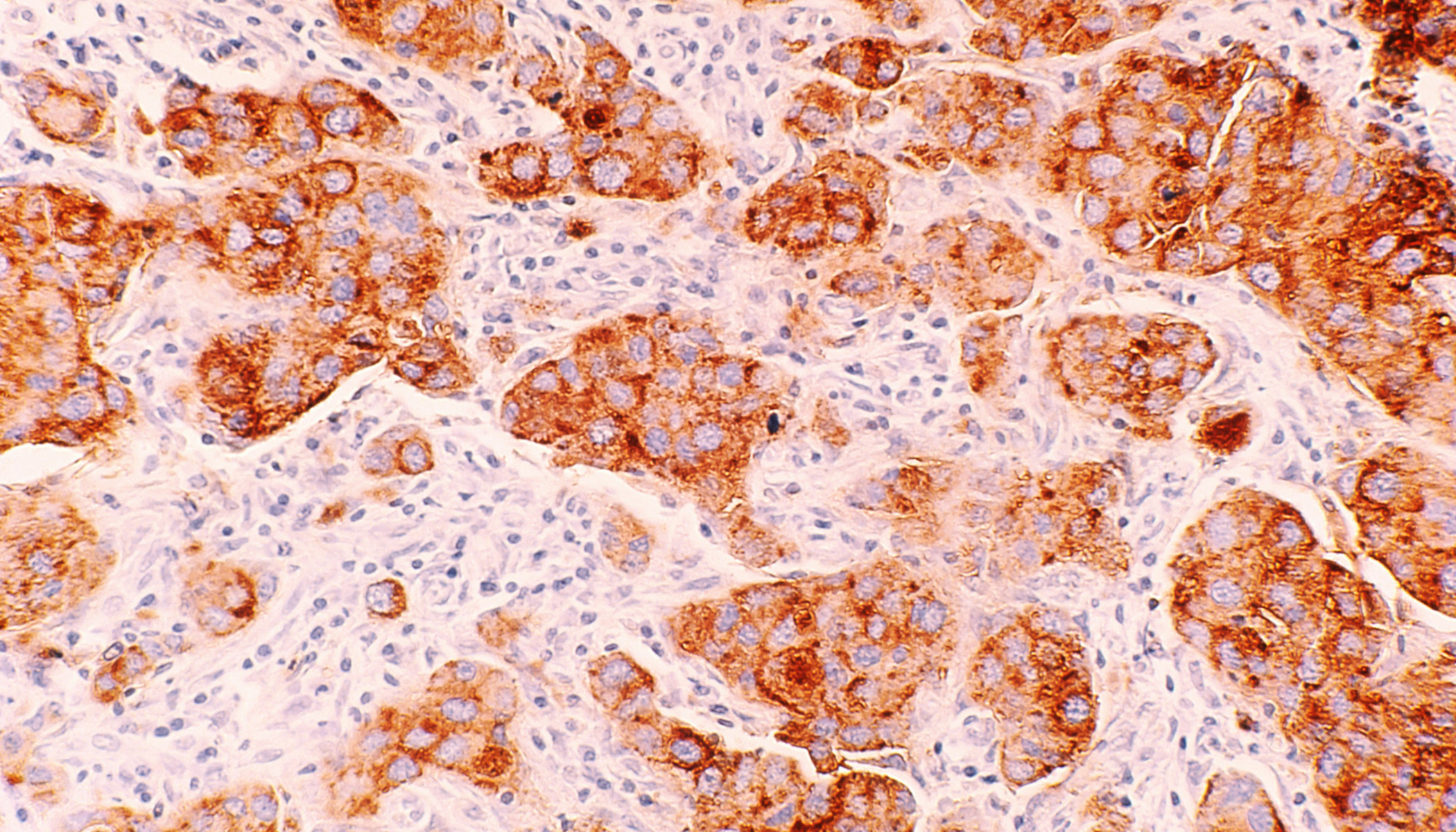

CamGaN’s technology reduces the cost of HB-LED manufacture by enabling the growth of gallium nitride (GaN), the light-emitting semiconductor found in HB-LEDs, on standard large-diameter silicon substrates. Current commercial LED processes grow GaN on 2- or 4-inch sapphire or silicon carbide substrates. The ability to grow on larger-diameter wafers increases batch yield by reducing the number of LEDs lost to edge effects, while the ability to grow on standard silicon wafers reduces cost and enables the use of automated semiconductor processing equipment.

“The CamGaN technology represents a significant breakthrough in the field of solid-state lighting,” said Professor Sir Colin Humphreys, Chairman and Co-Founder of CamGaN. “Although several players in the solid-state lighting industry have targeted large-diameter GaN-on-silicon as a key area for development, we believe that the ability to achieve consistently low defect densities in a thin-layer structure sets our technology apart from others.”

The ability to achieve low defect density is key to achieving high levels of light extraction, while the ability to limit layer thickness reduces manufacturing time and keeps cost down.

“We are pleased to have secured an opportunity for our technology with a major semiconductor brand that will accelerate mass production,” said Dr Andrew Lynn, Chief Executive of CamGaN. “This technology provides Plessey with a significant commercial breakthrough in a rapidly emerging industry.”

Plessey announced its plan to bring to market products for replacement bulbs based on the CamGaN GaN-on-silicon technology within the next two years. It also plans to develop a range of products based on smart-lighting concepts that incorporate existing Plessey sensing and control technologies.

Photo credit: You LED up my life by Kevin Dooley via Flickr